Home | Solutions | Pharmaceutical packaging control | Integral packaging control

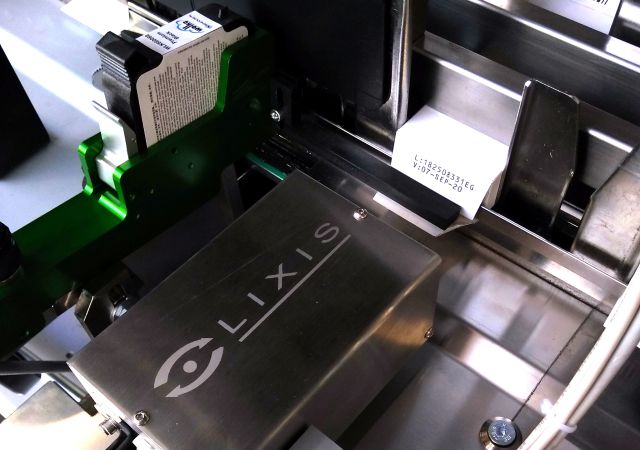

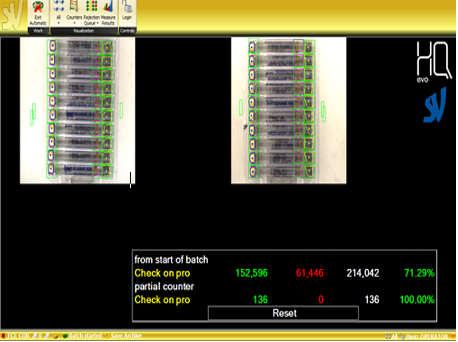

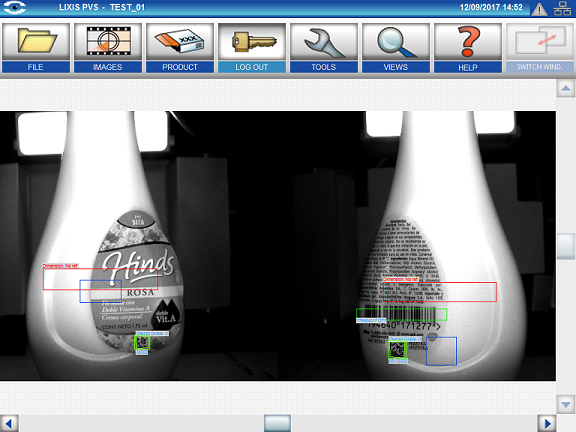

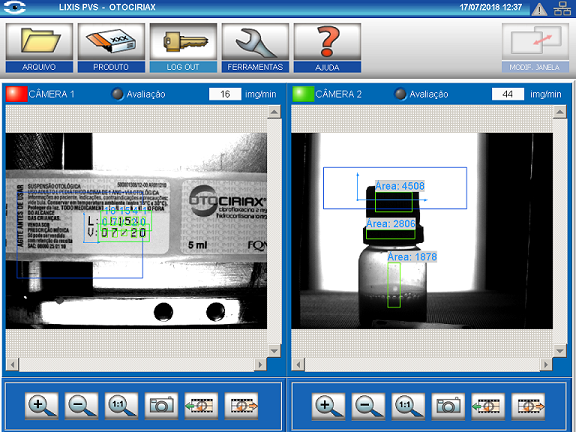

Multifunction systems capable of performing in-line control of alphanumeric printed character, 1D and 2D coding, packaging artwork and product integral inspection. Flexible equipment that can be adapted to different customized projects.

The flexibility of the software allows customization of all inspection requirements. Typical applications include: OCR/OCV control of printed characters, code control, vial borders, complete cases in one layer, Print Quality Verification (PQV) for ArtWork printed in-line. In addition, the equipment includes the Programmable Measurements tool which is a powerful and adaptable tool that allows a wide variety of special controls to be performed. This tool is a library that integrates a set of images allowing the operator to create (through a user-friendly interface) a customized application for image analysis with specific acceptance conditions.

Industrial Process Unit

Modular and scalable software structure

Graphic oscilloscope for error signal tracking

PLC integrated to the control of machine discards

Printer Management (integration with various brands/models)

Compliance with 21 CFR Part 11 and GMP

Easy to use

Voice assistant for equipment operation

Available in several languages

Easy Integration

Adaptability to existing packaging lines

Validation Documentation (IQ, OQ)

Use and Maintenance Manuals

Discard Management

Production Statistics

Access Levels

Ready for Industry 4.0

21CRF part 11

FDA

CE

cGMP

Win10

Total package integrity (product quality, cosmetic control and composition)

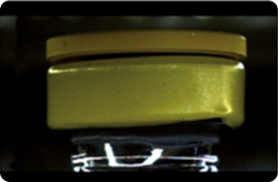

Controls the characters printed with laser technology on the aluminum seals of the bottles.

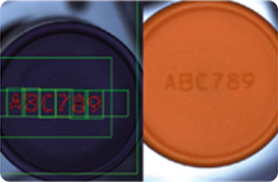

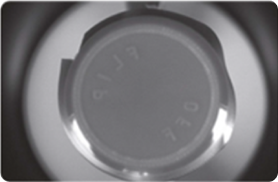

OCR/OCV inspection of printing on the flip-off color cover of the bottle with low contrast.

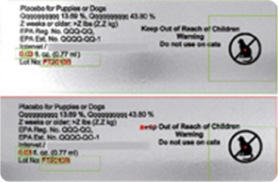

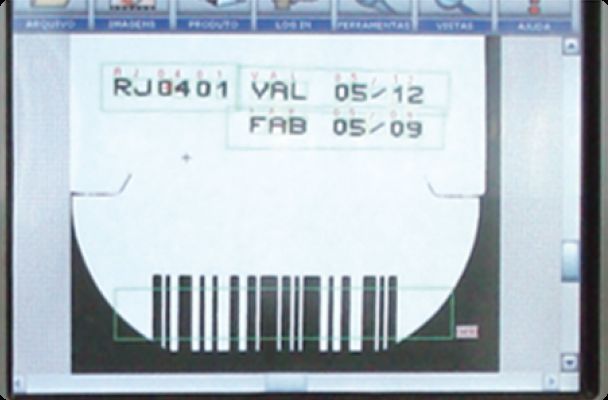

In-line OCR/OCV control of variable data on multiple labels.

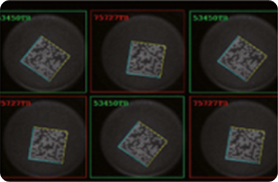

2D code control on the aluminum seal of the product. This 360° inspection is necessary due to the irregular position of the Datamatrix on the aluminum seal.

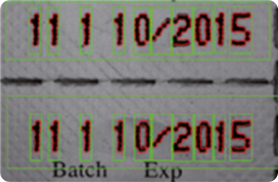

This application controls the printed area and checks for potential defects. This includes over or missing characters, printouts with missing areas and lines of text.

This application verifies the code identification and any variable data pre-printed or printed online. The OCR/OCV control performs the recognition and measurement of the characters, ensuring a careful printout.

This application controls the variable data printed on the blister foil by InkJet printing after sealing.

The control is also performed on the label of the vial.

In-line quality verification of printed data on multiple labels.

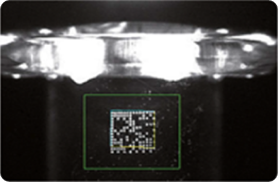

Control of UV Datamatrix codes printed on bottle caps.

This is a comparative control between the code printed on the product and the reference code determined at the beginning of the production batch. OCV supports linear pharmacode, high density linear codes and 2D codes (Datamatrix).

Controls laser-printed Datamatrix codes and variable data printed on the case flap. The system is able to manage the printer and the programming of the batch data to be printed online.

This application controls laser printing of 2D codes on syringes.

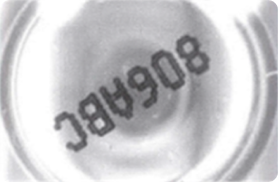

Allows character control at the bottom of the aluminum vial. This is achieved by means of a special optical setting that maximizes the contrast with the background.

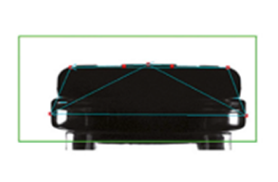

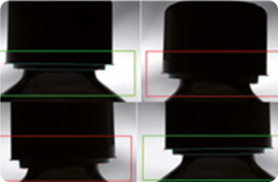

This application controls the correct positioning of lids on vials. This control performs a measurement of the angles and lines between cardinal points of the edges of the caps.

Checks the presence and position of sealing rings on vial lids. This control can be performed on conveyor belts or rotating machines.

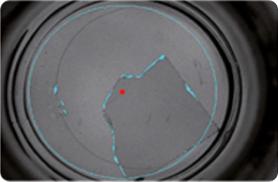

This application checks the integrity of the glass neck on vials by discarding damaged units. This control can be performed on conveyor belts or rotating machines.

The 360° cosmetic control checks the correct insertion of the seal, the presence of scratches, stains and tears in the closure, as well as the presence and color of the product closure.

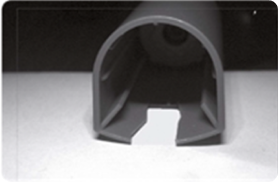

This application controls the correct formation of the bottle neck allowing the discarding of non-compliant bottles.

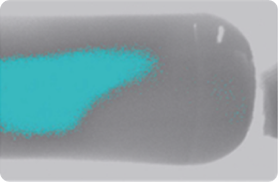

This application controls foreign bodies and impurities inside white PVC pipes.

This application checks that the UV (Ultraviolet) Label is present and applied in the correct position.

This application controls the correct assembly of the syringe. The measurement of distances, angles and number of extracted points ensure high quality inspection and efficient disposal of defective syringes.

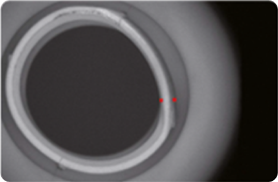

This application verifies the presence of glass fragments at the bottom of empty vials.

This application controls the blister sealing by identifying unsealed or defective seals.

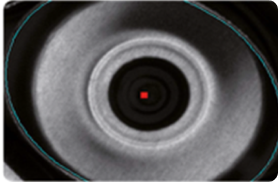

360° control of sealing, using pericentric optics. This solution makes it possible to control tears, bends and other defects with a single camera.

Inspection of cover integrity, checking for broken or missing parts.

Check the presence and integrity of the syringe flange. Programmable measurement calculates the distance of multiple points from the edge of the product to detect broken parts.

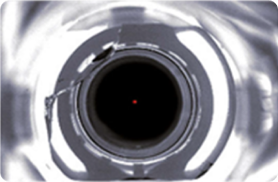

Detection of obstruction or failure in the drop counter orifice. This application performs this control by measuring the light passing through the same hole internally.

Programmable measurement allows detection of lid edge failures due to crushing.

This control uses a sophisticated lighting configuration that enhances the edges, while checking for completeness and defects on the bottom of the cases.

Integral Packaging Control is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that can be accessed from anywhere via a secure web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

Lima 1368

Martinez, Buenos Aires

T. +54 11 4836-2800

SÃO PAULO

Rua Mergenthaler 94

Villa Leopoldina, São Paulo

T. +55 11 3798-7800

GOIÁS

Av. María Miguel Abrão, 61 QD.61,

LT.01 Setor Sul Jamil Miguel, Anápolis, Goiás

CEP 75124-720

T. +55 62 3313-5620

Av. Rio Mixcoac 43

Del. Benito Juarez, CDMX

T. +52 55 8796 8004

SEA Vision S.r.l.

via Claudio Treves, 9 E/F

27100 Pavia (PV) – Italy

T. +39 0382 529576

Contact us

NEWSLETTER

Suscribe to our newsletter to receive our news.