Home | Solutions | Pharmaceutical packaging control | 2d and 3d product control

Equipment capable of detecting non-conforming products in shape and color in counting machines. In addition, 3D inspection can verify the thickness of the product, detecting defects that are not normally recognized by a standard vision inspection.

In conjunction with the Near Infrared Hyperspectral control it is able to perform an analysis of the product chemical composition.

Avoids possible products cross-contamination (shape and color dimension)

Product integrity

Ensures consumer safety

Industrial Process Unit

Modular and scalable software structure

Graphic oscilloscope for error signal tracking

PLC integrated to the control of machine discards

Printer Management (integration with various brands/models)

Compliance with 21 CFR Part 11 and GMP

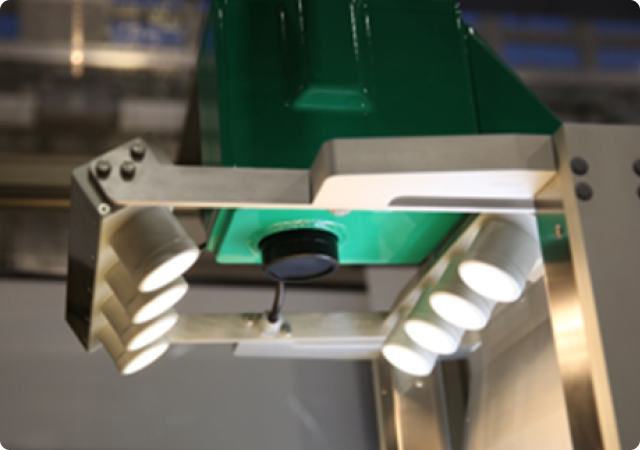

The combined vision system with 4 RGB cameras and a single high brightness white LED linear illuminator developed by SEA Vision is used to capture images at a frequency of up to 100 Hz.

The job of analyzing images and communicating the results to the machine is managed by the 2D control equipment software.

The vision system is fixed on the upper sliding plan of the product, close to the drop zone of the tablets inside the jars/bottles and discarded, individually, using flap systems placed at the end of each channel of the vibrating trays.

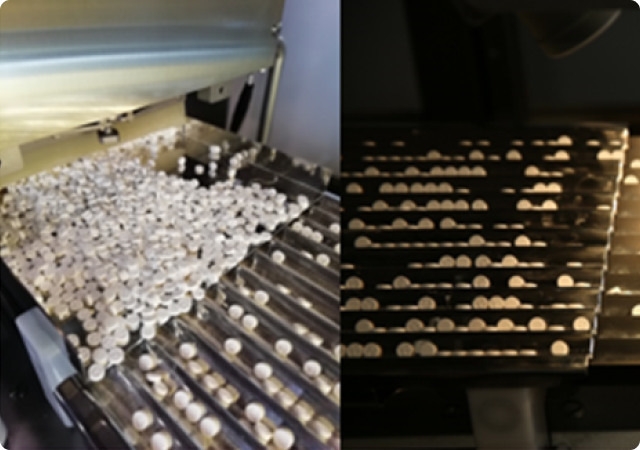

In addition, one of the innovative features of this vision system is the ability to track the tablets by the tracking system or follow their path along the end of the last vibrating tray before the drop. The counting machine, thanks to the sensors located in the final drop area, is able to count the product.

The tablets through the channel are uniquely identified by the vision system, one by one, and each tablet is discarded, tracing it on its way, allowing the single automatic rejection of the non-compliant tablet.

This is thanks to the vision system that sends a signal to the machine to tilt the deflector.

The 2D and 3D control systems in filling/counting machines ensure that only compliant products enter the jar/bottle after being inspected by the 2D-RGB control as well as by its hyperspectral camera.

With hyperspectral monitoring, we can characterize products, differentiate them and, consequently, identify cross-contamination based on the product active ingredient.

The system can detect with a sensitivity of 0.3 mg in 1 g of product (these values may be different in relation to other product, a higher sensitivity can be achieved).

The chemical information extracted from the system is converted to visualize the inspected products in real time, using grayscale images.

Avoids possible product contamination.

Analysis of 100% of the products.

Detection of foreign products.

Control of different active ingredients.

Dose control of the same active ingredient.

Fast, without impacting normal production speed.

Ensures patient safety.

In combination with the 2D control system, it is possible to install on the same machine the system that verifies the pictorial and geometrical characteristics of all tablets or capsules flowing in vibrating trays. More precisely: shape, size, presence of defects and color.

The 3D control can verify the height of the product, intercepting defects that are not normally recognized by a 2D control. The measurement is performed using an LED pattern and analyzing the shape of the resulting projections on the products.

Ensuring the integrity of the product for the patient

Taking care of the laboratory image

No impact on speed

100% control of the units

High performance cameras

Safety against cross-contamination

2D/3D Control is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that can be accessed from anywhere via a secure web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

Lima 1368

Martinez, Buenos Aires

T. +54 11 4836-2800

SÃO PAULO

Rua Mergenthaler 94

Villa Leopoldina, São Paulo

T. +55 11 3798-7800

GOIÁS

Av. María Miguel Abrão, 61 QD.61,

LT.01 Setor Sul Jamil Miguel, Anápolis, Goiás

CEP 75124-720

T. +55 62 3313-5620

Av. Rio Mixcoac 43

Del. Benito Juarez, CDMX

T. +52 55 8796 8004

SEA Vision S.r.l.

via Claudio Treves, 9 E/F

27100 Pavia (PV) – Italy

T. +39 0382 529576

Contact us

NEWSLETTER

Suscribe to our newsletter to receive our news.