High-resolution vision systems for blister filling control of all types of tablets, capsules, syringes, needles, ampoules and other products, in any type of forming material (PVC, aluminum and others), through automatic online inspection of 100% of the production, eliminating errors and reducing the costs linked to human control.

Easy-to-use and easy-to-learn SEA Vision software interface. Fast and efficient product programming and loading.

SEA Vision virtual voice assistant + Interactive on-screen help + Tutorial videos for product configuration (available in several languages).

Without decreasing the production speed in the blister machine.

Compliance with FDA 21 CFR part 11: auditing, data encryption and differentiated user level privileges.

User recognition by biometric fingerprint identifier.

PLC included for system monitoring and management of discard logic: machine stop (watchdog), shift register and device activation.

Detailed production reports and latest defective product images can be stored in the system for further analysis.

Possibility of product programming via e-mail and remote service via Internet.

Function for full system recovery with factory settings from included USB device.

Worldwide technical support network.

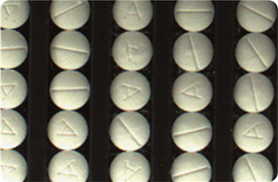

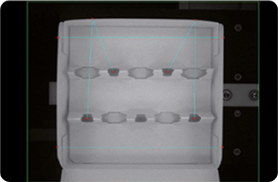

Controls the presence, color and integrity of the tablet/capsule in Alu-Alu blisters, Control of double product or foreign products in the alveolus.

White capsule control in white PVC. The softwafe also performs a chromatic measurement of product color, detection of stains on the product surface and cross-contamination.

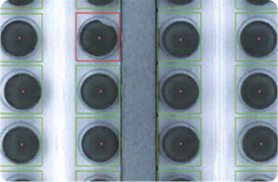

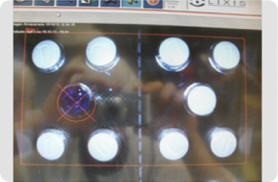

Presence, color, defects detected in transparent PVC blister (clear or opaque).

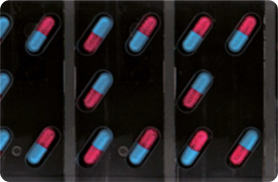

Control of the presence of blue / transparent capsules in blister packs. The control also checks for the presence of double product in the same cavity.

Control of presence, color and integrity of capsules in PVC blister packs. The system detects half open or excessively closed capsules.

Control of all the different components in transparent or white pharmaceutical trays or in cases.

Controls the presence of tablets passing through the vial filler guides. The system controls both the integrity and the correct filling of the bottle.

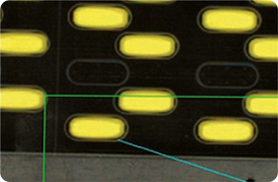

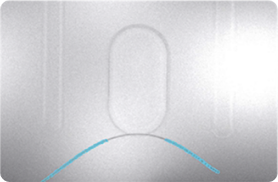

The blister passage is controlled by measuring the distance between a fixed point on the blister guide table and a variable point inside the blister.

Presence and color control of rings in vials. The software detects the pixel sizes and the distance between the rings.

Controls the correct formation of the container pack and the position of the components.

Controls impurities in blisters through the use of backlights under the blister.

Checks the integrity of the vial, filling control, rings.

Checks product integrity, label presence, spot check.

It is integrated to verify presence/absence of product after filling the alveoli.

Easy to use

Voice assistant for equipment operation

Available in several languages

Validation Documentation (IQ, OQ)

Use and Maintenance Manuals

Discard Management

Production Statistics

Access Levels

21CRF part 11

FDA

CE

cGMP

Win10

Total package integrity (product quality, cosmetic control and composition)

Multicamera Systems

OCR/OCV control on Alu foil – blister

Code control in Alu foil – blister

Access control via biometric fingerprint sensor

Miscellaneous inspection

Industrial compact hardware

Automatic backup

Easy Integration

Adaptability to existing packaging lines

Industrial process unit based system with Ehernet connection for remote support

Blister Control is natively integrated with Yudoo, the 4.0 pharmaceutical software suite for the full management of automation processes, digital quality, data analysis and for Track&Trace. A digital hub that can be accessed from anywhere via a secure web interface or dedicated devices.

A scalable and modular suite, including tools for automation (centralized management of production, workflows and timesheet), for the digital quality (creation of paperless systems, support systems for line clearance operations), for data analysis (analysis of production data, business intelligence dashboard, condition monitoring and predictive maintenance) and for Track and Trace (complete solutions for Level 3 and 4 of serialization, monitoring of serialization operations).

Yudoo offers multiple advantages such as the possibility to centralize production formats and data, avoiding duplicates and reducing work time. The suite can connect to existing company systems to retrieve updated data exactly from where they are.

Lima 1368

Martinez, Buenos Aires

T. +54 11 4836-2800

SÃO PAULO

Rua Mergenthaler 94

Villa Leopoldina, São Paulo

T. +55 11 3798-7800

Av. Rio Mixcoac 43

Del. Benito Juarez, CDMX

T. +52 55 8796 8004

SEA Vision S.r.l.

via Claudio Treves, 9 E/F

27100 Pavia (PV) – Italy

T. +39 0382 529576

Contact us

NEWSLETTER

Suscribe to our newsletter to receive our news.